PhD candidate continues to build links between industry and academia

15 October 2018

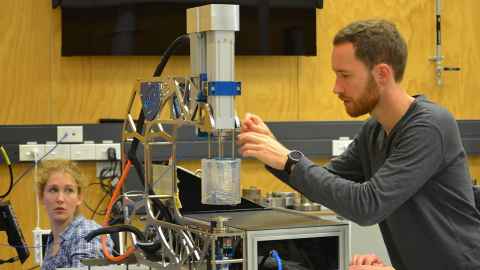

A recent presentation at our Newmarket Campus showcased one of the projects being worked on by members of the Centre for Advanced Composite Materials.

The aim was to show how links between academia and industry can develop through shared research projects.

“This project has a strong industry background,” said PhD student Tino Hermann. “It's not just academic research, you could say academia is meeting real industry applications in this case.”

Tino, under the supervision of Professor Simon Bickerton, focuses his research on the quality assurance of carbon fibre parts used in mass production. Tino and Professor Bickerton both have connections with BMW, and the German manufacturer is intending to use the technology in the mass production of its premium vehicles, particularly in models where weight-saving is essential.

“Take the BMW i series, they're meant to be electric vehicles, and a lot of weight is consumed by the battery pack, so the company is compensating for this issue by using materials such as carbon fibre,” Tino explains.

“This leads to some issues within the production, because the material hasn't actually been used for mass production so far. Usually it's more common in industries where really high performance and costs can be covered.”

Tino’s research involves detecting “features” within a given carbon fibre textile that could potentially lead to a defect in the final part. By detecting these features and defects ahead of time, they can ensure the textiles are suitable for use in the parts that go on the final production models.

The long-standing relationship with the BMW Group started when Professor Bickerton was seconded full-time to BMW for a 3 year period from 2012. Tino interned with the company from 2013, and crossed paths with Professor Bickerton, project leader within the company by this time. He then went on to complete his Masters in cooperation with Technische Universität Dresden and the BMW Group, which exposed him to the type of research and development processes available to these large companies.

“Those companies have a huge research and development unit,” Tino said. “So you of course learn a lot of new things over there and how things are done within big industries. It is proper problem-solving thinking."

While their approaches and motivations are often different between industry and academia, the two still depend on each other.

“Academia will always serve industry, there really is a symbiosis between those two. Industry is much more focused on time and costs, and this creates a bit more of a high-pressure environment I would say. Academia has the time to really think about fundamental issues.”

With only a few months left in what Tino describes as being a challenging project that’s given him valuable experience, there are still options for what the project’s next steps might be. There’s a possibility that some elements of the research could still be commercialised, with the aim to continue to build connections for Tino, Professor Bickerton and the Centre for Advanced Composite Materials.