Bioengineers use Artificial Intelligence to transform hip surgery

10 February 2022

Formus Labs, a company that grew out of research done at the Auckland Bioengineering Institute (ABI), is set to transform orthopaedic surgery, with the world’s first automated 3D pre-operative planner for joint replacements.

Formus Labs has recently raised US $5 million to commercialise its cloud-based fully interactive platform that provides surgeons with an automated 3D and patient-specific planner for hip and other joint replacement surgeries

In partnership with global orthopaedic technology leader, Zimmer Biomet, the inaugural product of the Formus Platform, Formus Hip, will be released in Australia and New Zealand in February.

Formus Hip is currently being used by dozens of surgeons in hospitals on both sides of the Tasman. Its wider release in both countries will be followed by a focused and strategic product evaluation in the United States where the company expects to get FDA approval in mid-2022.

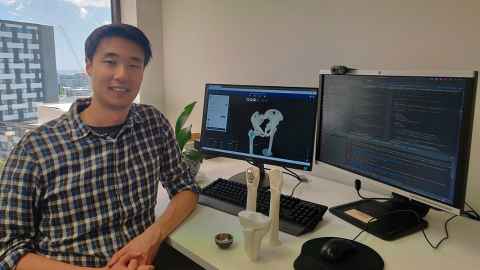

Formus Labs was founded by bioengineer Dr Ju Zhang, who is now the company’s CEO. It came out of his PhD and postgraduate research at the ABI, University of Auckland, in which he was supervised by Professor Thor Besier – Professor Besier is co-founder of Formus Labs and its chief scientific officer.

Formus harnesses the expertise and research done over years at the ABI by Professor Besier and his team into the mechanisms of musculoskeletal systems, injury and disease, research that combines medical imaging with computational modelling.

Surgeons typically rely on 2D x-rays to estimate the best size and orientation of implants ahead of surgery, a process that relies on manual image processing and can take weeks.

The Formus Labs software allows a surgeon to get an automated, pre-operative a 3D plan that identifies the best implant size and orientation joint replacement within an hour.

As the current process depends on human assessment, and the particular expertise of each individual, joint replacements are frequently flawed. “Globally, one in five knee replacements are unsatisfactory and one in ten hip replacements need revision, which ends up costing the orthopaedic industry US $10 billion per year,” says Dr Zhang.

“Half of them fail because they’re the wrong size or positioned incorrectly. You wouldn’t try to build a car without knowing the right parts that fit and it shouldn’t be any different when it comes to joint replacement surgery.”

You wouldn’t try to build a car without knowing the

right parts that fit and it shouldn’t be any different when it comes to joint replacement surgery

Importantly, Formus Labs software allows for pre-operative planning that is personalised to each patient. “This technology allows surgeons to identify the right size - the right-sized stem and for the right-sized socket, for instance – and the right angle of orientation for each implant.”

“Most of us know someone that has had a joint replacement, but few know just how complex, variable, and costly the process can be. Our goal is to make orthopaedic surgery as simple as it can be, by arming surgeons with the latest cutting-edge technology, so every joint replacement has a Formus plan that reduces the need for revisions, instils confidence, and facilitates better outcomes for patients and at a lower cost.”

Co-founders of Formus Labs include other researchers at the ABI, including Associate Professors Paul Monk (who is also an orthopaedic surgeon) and Justin Fernandez. They, along with Professor Besier, continue to give scientific/clinical advice to the company which is, for now, based at Cloud 9 - a collective of companies that are independent, but based in the ninth floor of the University’s ABI building, where they are in close contact with researchers within the Institute.

Being located in the same building as ABI researchers and “being able to go downstairs to talk to world experts in biomechanics and to one of the top orthopaedic surgeons in New Zealand or, students about their technology research projects, has been invaluable,” says Dr Zhang.

“Also, being located on Cloud 9, means we’re amongst the ecosystem of companies who have spun out of ABI research, companies that are at various stages of the same journey, where we can just trade notes and share stories. Knowing you’re not alone in this, is really helpful.

“It’s a unique situation, one that really encourages the translation of research into commercialisation, so our technology can have a real-world impact in a clinical context.”

The latest investment was led by VC firm GD1 (Global from Day 1), with participation from Punakaiki Fund, Icehouse Ventures, Pacific Channel, Flying Kiwis and Uniservices.

The company will use the latest round of funding to expand its team, both in New Zealand and the US, including key marketing and commercial hires, plus product development and engineering roles.

In the long run, “we aim to become the standard of care for surgical planning, in the world,” says Dr Zhang.

Media contact

Margo White I Media adviser

Mob 021 926 408

Email margo.white@auckland.ac.nz